Stellantis, in collaboration with Saft, a subsidiary of TotalEnergies, has announced the global premiere of a groundbreaking prototype vehicle powered by the Integrated Intelligent Battery System (IIBS). This innovative technology, now entering real-world testing, marks a milestone in the evolution of electric mobility and energy storage, positioning Stellantis and Saft at the forefront of sustainable innovation in the automotive sector .

Redefining the Future of Energy Storage

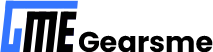

At its core, the IIBS represents a paradigm shift in EV battery design. Unlike traditional systems that rely on separate components such as inverters and chargers, IIBS consolidates these elements directly into the battery. This design not only optimizes space but also enhances performance and reduces overall vehicle complexity.

By integrating multiple functions within a single unit, Stellantis and Saft are reshaping how electric vehicles are engineered and maintained. The result is an architecture that is lighter, more efficient, and more sustainable, offering tangible benefits for both automakers and end users.

The Peugeot E-3008, built on Stellantis’ STLA Medium platform, has been chosen as the first vehicle to showcase this pioneering technology. This model will serve as a rolling laboratory for IIBS, allowing engineers to collect real-world data that will influence the next generation of electric vehicles across Stellantis’ wide portfolio of brands.

The Road to Innovation

The journey to this milestone has been years in the making. Stellantis and Saft collaborated closely with E2CAD, Sherpa Engineering, and leading French research institutions including the CNRS (French National Centre for Scientific Research), Université Paris-Saclay, and Institut Lafayette. Together, these partners formed a multi-disciplinary team of 25 engineers and researchers, pooling expertise in energy storage, power electronics, and vehicle systems design.

The first stationary prototype of IIBS was launched in mid-2022, proving the validity of the technical concept. It secured numerous patents and demonstrated efficiency gains that captured the attention of the wider energy sector. Building on this success, Stellantis has now transitioned the project into mobile applications, moving closer to commercial readiness.

This collaborative approach underscores a key theme of the IIBS project: innovation through simplification. By challenging conventional design assumptions, the project has created a scalable technology that can serve not only cars but also rail, aerospace, marine, and industrial applications.

How the Integrated Intelligent Battery System Works

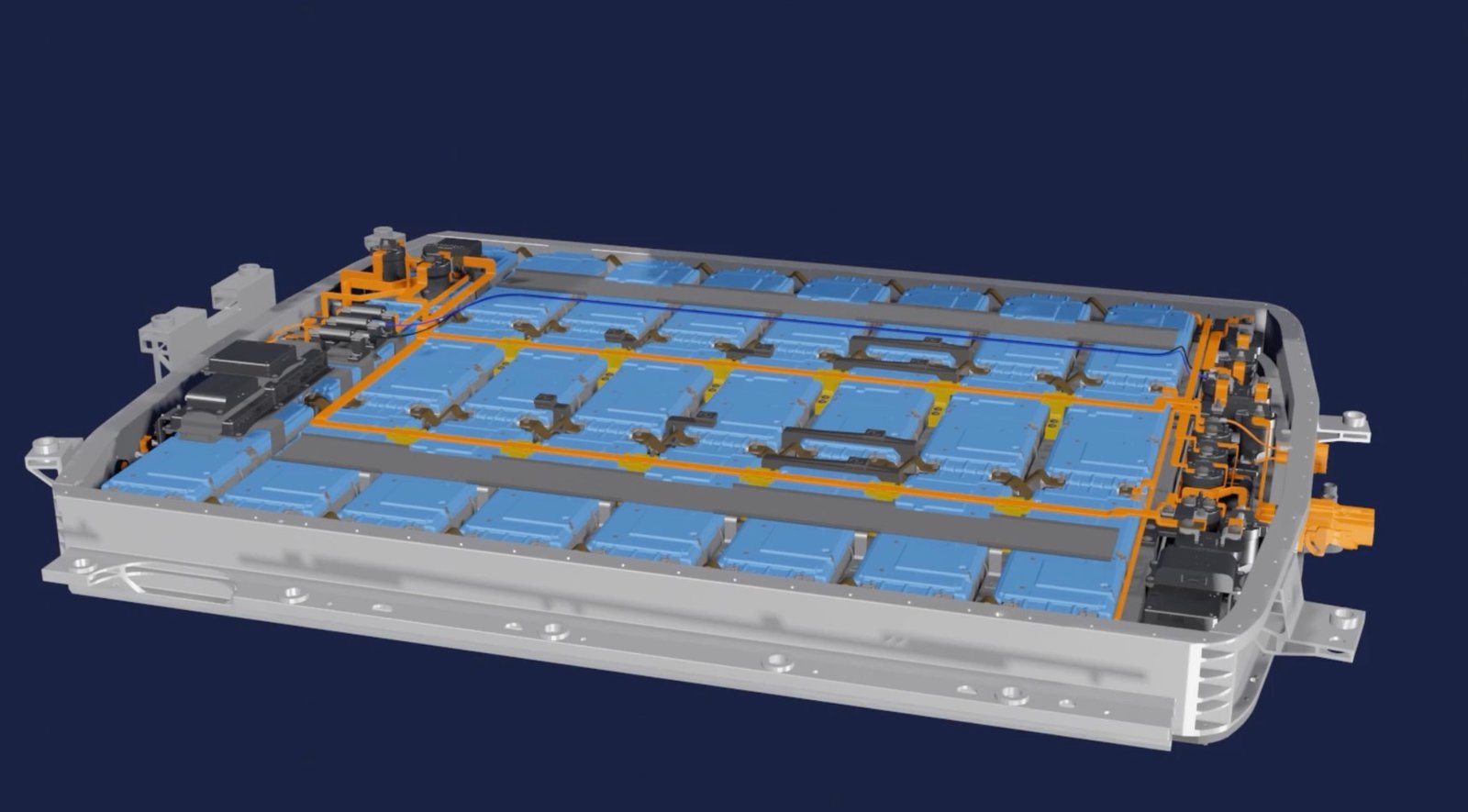

The IIBS represents a complete rethink of the EV powertrain. Traditionally, batteries provide raw energy, which is then processed through external inverters and chargers before being delivered to the motor or grid. This requires multiple components, wiring, and interfaces, adding weight, cost, and complexity.

IIBS simplifies this architecture by embedding the inverter and onboard charger directly inside the battery housing. This integration enables:

- Direct AC and DC power delivery, making the system compatible with multiple energy flows.

- Simultaneous support for high-voltage and 12V systems, ensuring seamless operation of both propulsion and auxiliary functions.

- Reduced energy losses by eliminating intermediate conversions, thereby boosting efficiency.

This simplification translates into significant real-world benefits:

- Up to 10% higher energy efficiency during WLTP testing cycles.

- 15% more power output from the same-sized battery (172 kW vs 150 kW).

- 40 kg weight reduction and 17 liters of additional space, enhancing aerodynamics and design flexibility.

- 15% faster charging times, reducing AC charging sessions from 7 hours to approximately 6.

- Simpler maintenance and greater recyclability, as batteries can be repurposed more easily at the end of their automotive life .

Voices from the Industry

Ned Curic, Chief Engineering & Technology Officer at Stellantis, emphasized the broader vision:

“This project embodies our conviction that simplification is innovation. By redesigning and streamlining the EV powertrain, we have created a system that is lighter, more efficient, and more cost-effective. These advances enable us to deliver superior electric vehicles at prices that are accessible to a wider audience.”

Hervé Amosse, Executive Vice President of Energy Storage Systems at Saft, highlighted the global relevance of the project:

“The Integrated Intelligent Battery System is a testament to Saft’s leadership in advanced energy solutions. Its adaptability across industries—from automotive to aerospace—demonstrates its potential to shape the energy landscape for decades to come. By combining intelligence, flexibility, and sustainability, we are setting the stage for the next generation of energy systems.”

Strategic Importance and Future Roadmap

The IIBS initiative is closely aligned with France’s national “France 2030” strategy, which aims to accelerate innovation in sustainable technologies. Phase two of the project, launched in June 2025, focuses on real-world driving tests under varied conditions. These tests are designed to validate performance, reliability, and scalability, paving the way for industrial deployment.

Stellantis plans to integrate IIBS into its vehicle lineup before the end of this decade. Given the group’s expansive portfolio—including Peugeot, Citroën, Fiat, Opel, Jeep®, Maserati, and more—the technology has the potential to reach millions of consumers worldwide.

Beyond cars, the potential applications of IIBS are vast. Rail networks, marine transport, aerospace systems, and even data centers could leverage the system’s efficiency and modular design. This versatility ensures that the innovation delivers value across multiple industries, reinforcing Stellantis and Saft’s leadership in sustainable electrification.

Broader Implications for the EV Market

The unveiling of IIBS comes at a critical time for the global automotive industry. With regulatory pressures mounting, consumers demanding greater affordability, and infrastructure challenges persisting, automakers are under pressure to deliver EVs that are not only sustainable but also practical and cost-competitive.

By reducing weight, improving efficiency, and simplifying maintenance, IIBS directly addresses these challenges. It offers a pathway to lower production costs, enhanced vehicle range, and a smoother ownership experience—all factors that could accelerate EV adoption globally.

Moreover, the system’s adaptability ensures resilience against future technological shifts. Whether battery chemistry evolves toward solid-state, lithium-sulfur, or other next-gen solutions, IIBS can accommodate these advancements, protecting Stellantis’ long-term investment.

Conclusion

The launch of the world’s first vehicle prototype featuring the Integrated Intelligent Battery System is more than a technological achievement—it is a vision for the future of mobility and energy. Through collaboration, innovation, and a commitment to sustainability, Stellantis and Saft are pioneering solutions that promise to transform not just cars, but entire industries.

As phase two testing unfolds and integration into production vehicles draws nearer, the IIBS stands as a clear signal: the next era of electrification will be smarter, simpler, and more sustainable.