Munich — The BMW Group’s Steyr plant is preparing to begin mass production of fuel cell systems. Starting in 2028, the third generation of BMW’s hydrogen drive system will be manufactured there. Competence centers in Munich and Steyr are already working on the first prototypes, while additional components will be supplied by the technology center in Landshut. Joachim Post, BMW AG Board Member for Development, states, “The launch of BMW’s first fuel cell production model in 2028 will introduce a highly efficient, zero-emission powertrain to our diverse and technology-forward product lineup.” He adds that selecting Steyr as the production site highlights BMW’s strong commitment to innovation in Europe, with the Munich and Steyr competence centers playing a vital role in developing advanced fuel cell technologies.

The third generation of BMW’s fuel cell system is designed to be smaller, more powerful, and more efficient. The first generation, developed entirely by Toyota, was installed in the BMW 535iA in 2014. The second generation debuted in the BMW iX5 Hydrogen pilot fleet, where BMW took over development of the full system while Toyota supplied the individual fuel cells. For the latest generation, BMW and Toyota are collaborating to jointly develop the powertrain for passenger vehicles, leveraging the core fuel cell technology for both commercial and passenger use. This partnership allows both companies to share resources in development and procurement, while producing models tailored to their respective brands.

Key advancements in the third generation of fuel cell technology include:

Compact design: The fuel cell system’s size has been reduced by approximately 25%, thanks to a significant boost in power density, allowing for a much smaller build than the previous generation.

High integration: This generation is designed to be easily incorporated into future vehicle architectures, supporting a flexible, technology-neutral strategy that enables a wide range of drive options for customers.

Enhanced components and efficiency: The system promises much higher efficiency than before through upgraded components—developed jointly with Toyota—and improved operational strategies. These improvements lead to greater driving range and power output while reducing energy use, marking a notable upgrade from the second generation.

BMW Group’s technological expertise in Munich

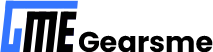

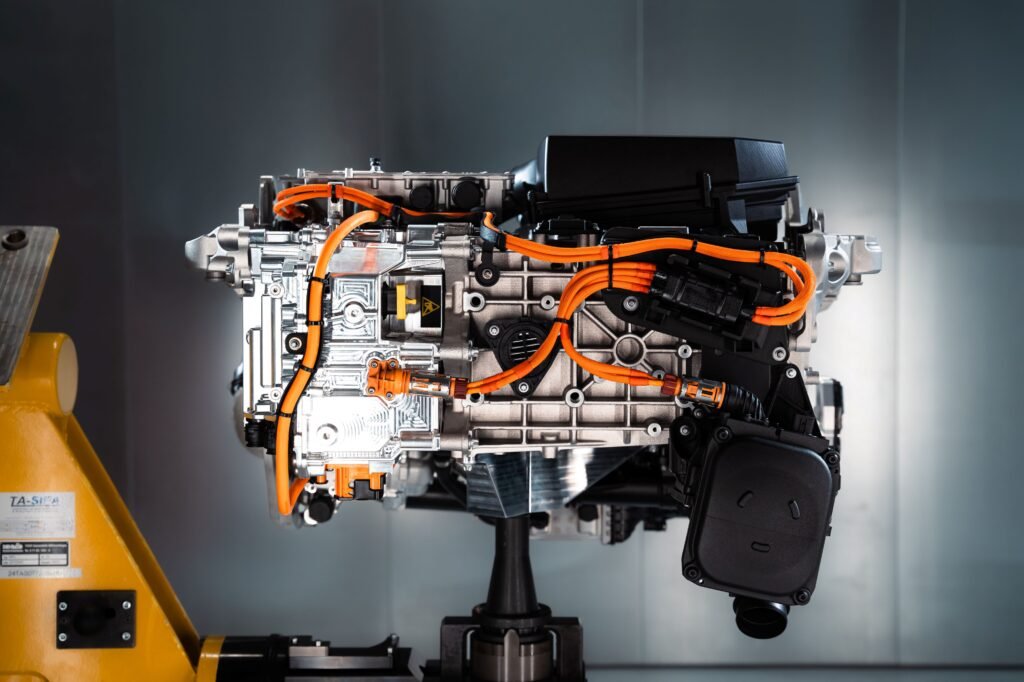

At BMW’s hydrogen competence center in Munich, prototypes of these highly efficient fuel cell systems are being developed. The fuel cell generates electricity through an electrochemical reaction where hydrogen from the tanks reacts with oxygen from the air, powering the vehicle’s electric motor.

The system includes the fuel cells and all supporting components necessary for efficient operation, such as cooling systems and hydrogen and air subsystems. Its compact design ensures that the entire drivetrain meets BMW’s renowned standards for performance and safety.

Current prototype production focuses on refining assembly, testing, industrialization, quality assurance, and scalability. Simultaneously, prototypes are used to develop and validate operational strategies at both system and vehicle levels—critical steps toward preparing the technology for mass production.

Series production at BMW Group Plant Steyr

From 2028, Steyr will begin mass production of fuel cell systems, leveraging decades of BMW’s expertise in developing and producing various drive systems across its model lineup. New testing equipment and production facilities are under construction, with buildings being adapted to integrate and continuously improve this new technology.

Klaus von Moltke, Senior Vice President of Engine Production at BMW AG and Plant Director at Steyr, remarks: “We are proud to add another innovative drive technology alongside the latest electric motors and combustion engines at Plant Steyr. Our on-site development expertise underscores the plant’s role as a leading example of BMW Group’s technology-neutral approach.”

Component manufacturing at BMW Group Plant Landshut

“The Landshut plant handles key component production for fuel cell vehicles. Starting late May 2026, construction of new equipment for series production of the hydrogen-specific BMW Energy Master will commence. This unit manages vehicle power supply from 400 to 800 volts and interfaces with the high-voltage battery. It includes specialized components tailored for fuel cell applications”.

The first prototypes of the hydrogen Energy Master will be produced mid-2026 near the Dingolfing plant, where prototypes for the Neue Klasse Energy Master were also built.

As with the BMW iX5 Hydrogen pilot vehicles, Landshut will produce housings and pressure plates for the upcoming generation of models.